스포트라이트

제조 공정 엔지니어, 제조 시스템 엔지니어, 제조 개발 엔지니어, 제조 생산 엔지니어, 제조 설계 및 개발 엔지니어, 제조 공정 개발 엔지니어, 제조 설계 전문가, 생산 설계 엔지니어, 공정 설계 엔지니어, 제조 설계 분석가.

If you’ve ever bought a mass-produced product, it was probably manufactured. Modern manufacturing relies on innovative designs and efficient processes to transform ideas into goods we can use in the real world!

That’s why the manufacturing sector is fundamental to so many industries, from vehicles to appliances and other consumer goods—and Manufacturing Design Engineers are the experts who make it all possible.

They create and implement the complex processes needed to move designs from the concept stage to production, helping optimize manufacturing methods while ensuring product quality and functionality along the way.

Blending principles of mechanical engineering, material science, and industrial design, their work is vital for manufacturers to stay cost-effective and competitive. This ultimately contributes to wider economic growth and technological advancement across multiple industries!

- Innovating product design and manufacturing processes

- Enhancing efficiency and sustainability in production

- Contributing to technological advancements in various industries

근무 일정

Manufacturing Design Engineers typically work full-time, with overtime needed to meet project deadlines. The role may include occasional travel for plant visits, supplier meetings, and industry conferences.

일반적인 의무

- Collaborate with cross-functional teams to develop and refine product designs

- Select appropriate materials and manufacturing processes for products

- Implement cost-reduction strategies and improve production efficiency

- Conduct product and process simulations using computer-aided drafting and manufacturing software

- Review product quality and oversee prototype testing

- Analyze production data to look for problems and inefficiencies

- Offer technical guidance and support to manufacturing teams

- Maintain detailed documentation regarding manufacturing processes

- Stay updated on trends and technology advancements related to manufacturing

- Integrate new technologies such as automation and robotics

- Study industry best practices, lead continuous improvement

initiatives, and focus on lean manufacturing principles

추가 책임

- Work with suppliers to ensure the availability of suitable materials

- Participate in research and development

- Evaluate environmental impacts; ensure compliance with industry standards

- Coordinate with official agencies to keep up with changing requirements such as product safety regulations, laws, and standards

소프트 스킬

- 적응성

- 분석적 사고

- 세부 사항에주의

- 명확한 커뮤니케이션

- 창조성

- 독립

- 혁신

- 지도력

- 문제 해결

- 자기 동기 부여

- 팀워크

기술 능력

- Experience in product design and development

- Familiarity with lean manufacturing and continuous improvement methodologies

- Industrial control software (Computer numerical control; programmable logic controller; and supervisory control and data acquisition software)

- Knowledge of environmental and safety regulations

- Knowledge of manufacturing processes and materials

- Proficiency in CAD and CAM software

- Skills in project management and cross-functional collaboration

- Understanding of quality control and assurance principles

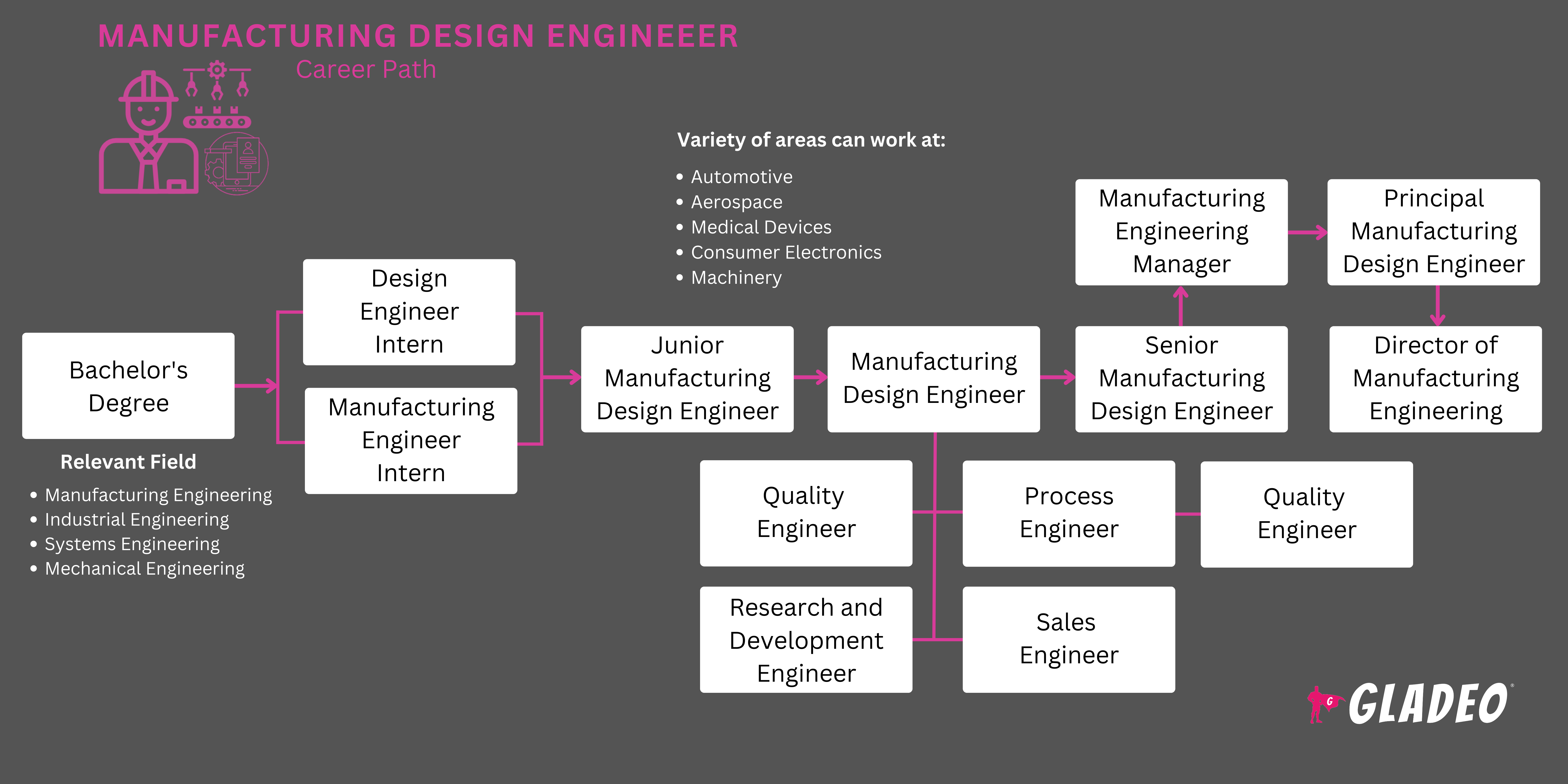

- 자동차 제조업체

- 항공우주 기업

- Consumer electronics firms

- Industrial machinery manufacturers

- Medical device companies

- 연구 및 개발 조직

The responsibilities of a Manufacturing Design Engineer lie at the nexus between promoting creative design ideas and incorporating practical manufacturing processes. Sometimes design aspects must be sacrificed in order to make a product idea feasible and cost-effective to produce.

Their duties may shift from desk work to on-site involvement, which can add up to long hours—especially when deadlines are coming up or there is a production problem. Meanwhile, the worksite environments are usually noisy, busy, and sometimes hazardous. But the pressure is on to keep things running because production downtime means lost revenue.

Because manufacturing technologies evolve, Manufacturing Design Engineers must keep up with trends so processes run as efficiently as possible. This requires continuous learning and studying what the competition is up to!

The integration of automation has been a transformative trend, with increasingly sophisticated and flexible automation systems able to adapt to varying production demands. In addition, robotics combined with advanced AI are also enhancing efficiency, precision, and safety on the manufacturing floor.

Meanwhile, the rise of Industry 4.0 is reshaping manufacturing into a more data-driven and interconnected domain. Smart factories, underpinned by the Internet of Things, are turning manufacturing facilities into intelligent environments using sensors and connected devices to monitor and optimize processes in real-time.

Another crucial trend is the emphasis on sustainability and eco-friendly practices. Manufacturers are increasingly adopting green processes, focusing on reducing waste, conserving energy, and minimizing their carbon footprint. 3D printing and additive manufacturing are playing a vital role in these endeavors.

Manufacturing Design Engineers may have been fascinated by how things are made, enjoying activities like building models, disassembling electronics, or crafting. Their interests likely included STEM subjects, with hobbies such as robotics clubs, woodworking, or computer programming. They might have had an interest in design and drawing, too!

- Manufacturing Design Engineers typically need a bachelor’s in manufacturing design engineering, mechanical engineering, industrial engineering, or a related field

- Relevant coursework may include:

- Applied Probability & Statistics

- Calculus for Computer Science

- 컴퓨터 지원 설계

- Computer-Aided Engineering

- Electrical Circuits & Systems

- Environmental and Safety Standards

- Industrial Automation

- Manufacturing Processes

- 재료 및 제조

- 재료 과학

- Mechanical Design

- Product Design Optimization

- Many students go for a 5-year dual bachelor’s and master’s degree

- Internships in manufacturing or design firms can provide practical experience

- Optional professional certifications such as Six Sigma, Lean Manufacturing, or Project Management are great ways to boost one’s knowledge and capabilities

- Workers with engineering degrees can take the Fundamentals of Engineering exam, earn a National Council of Examiners for Engineering and Surveying’s Engineer In Training certification, and pursue a National Society of Professional Engineers’ Professional Engineer license when the time is right

- Seek an ABET-accredited program in mechanical engineering or industrial engineering

- 사용 가능한 재정 지원 및 장학금 기회와 등록금 비용을 비교합니다.

- 프로그램 형식(캠퍼스 내, 온라인 또는 하이브리드)을 결정합니다.

- 최신 실험실 및 연구 공간에 대한 교수진의 자격 및 시설 평가

- 풍부한 학습 경험을 위해 업계/연구 기관과의 파트너십을 조사합니다.

- 취업률 및 동문 네트워크의 강도와 같은 졸업 후 결과를 고려하세요.

- Reach out to do an informational interviews with a working Manufacturing Design Engineers

- Check out “A Day in the Life of a Manufacturing Engineer”

- Watch videos and read blogs and publications related to the field to stay informed about industry trends

- 채용 공고를 검토하고 직무 설명을 읽어 고용주가 현재 어떤 자격 요건과 전문성을 원하는지 확인하세요.

- In high school, focus on math (algebra, geometry, trigonometry, calculus), physics, computer science, chemistry, and design courses

- Apply for engineering scholarships like the SME Education Foundation Scholarship

- In college, delve into courses on manufacturing processes, CAD/CAM, and material science

- Engage in extracurricular activities like engineering clubs or design competitions

- Participate in internships or co-op programs to gain real-world experience

- Join professional organizations and forums related to manufacturing and design engineering

- Join manufacturing design engineering-related discussion groups like Engineers Edge

- 이력서 및 대학 지원서를 위해 모든 업무와 학업 성취도를 추적하세요.

- Seek internships in manufacturing design to gain practical work experience

- Use a Manufacturing Design Engineering resume template

- Include relevant keywords such as CAD, Process Optimization, Lean Manufacturing, etc.

- Check out some current job postings to search for relevant keywords to include, if applicable to your resume

- Enhance your resume by acquiring certifications in key areas like CAD software (SolidWorks, AutoCAD) or process improvement methodologies (Six Sigma)

- Participate in competitions or collaborative projects focused on manufacturing design to gain attention

- 관련 용어와 트렌드를 숙지하여 면접에 대비하세요.

- Brush up on areas like 3D printing, robotics, and sustainable design practices

- Create a digital portfolio showcasing your design projects and contributions. Detail your roles, skills used, and the impact of your work

- Jobs are often found through networking, so make connections by going to professional association events. Let your network know you’re looking for work!

- Be active in online forums related to manufacturing design engineering

- Use LinkedIn and specialized engineering forums to discover job opportunities

- 잠재적 고용주를 조사하고 해당 채용 페이지를 방문하여 채용 정보를 확인하세요.

- Ask former supervisors and/or college professors for references or recommendation letters

- Utilize your school’s career center for help with resume and interview preparation

- Ask your program manager if they have ties with local employers or recruiters

- 면접을 위한 전문성 있는 복장

- Consider specialized certifications or a master’s degree to deepen your expertise

- Discuss advancement opportunities with your supervisor. Try to get involved in higher-level decision-making

- Volunteer for challenging manufacturing projects to demonstrate your skill and adaptability

- 경력 및 고용주에게 도움이 되는 추가 교육 및 훈련을 적극적으로 찾아보세요.

- Stay current with the latest software, tools, and manufacturing methodologies

- Build strong relationships with colleagues, management, and clients

- 주니어 동료 또는 인턴을 멘토링하여 리더십 기술 개발하기

- Consider switching employers if necessary to advance your career. Move to an area where there are more job opportunities in your field, if necessary to advance

- For example, states with high levels of industrial engineer employment include Michigan, California, Texas, Ohio, Illinois, Minnesota, Wisconsin, Indiana, and Connecticut

- Get your Professional Engineer license to demonstrate your commitment to the field

- Keep active in professional associations like the Society of Manufacturing Engineers to grow your network and reputation. Go to conferences and offer to give speeches

- Contribute scholarly articles to industry journals or publications like Manufacturing Today to showcase expertise

웹사이트

- 아벳

- 미국 공학 교육 학회

- 미국 기계 공학회

- Autodesk

- 산업 및 시스템 엔지니어 연구소

- 국제 자동화 학회

- Manufacturing Today

- Manufacturing USA

- 엔지니어링 및 측량을위한 전국 심사관 협의회

- National Institute of Standards and Technology

- 국립 전문 엔지니어 협회

- 제조 엔지니어 협회

- SolidWorks Community

- 여성 엔지니어 협회

- 기술 학생 협회

책

- Introduction to Manufacturing: An Industrial Engineering and Management Perspective, by Michel Baudin and Torbjørn Netland

- Manufacturing Processes for Engineering Materials, by Serope Kalpakjian and Steven Schmid

- The Design of Everyday Things, by Don Norman

- The Materials Sourcebook for Design Professionals Hardcover, by Rob Thompson and Martin Thompson

Manufacturing Design Engineering is a dynamic and evolving field. Sometimes the pressure to meet production demands and deadlines can be intense. For those who are curious about other options, check out the below list of related career fields!

- CAD 기술자

- 화학 엔지니어

- 전기 엔지니어

- 인적 요소 엔지니어

- 산업 디자이너

- 산업 엔지니어

- 재료 엔지니어

- 기계 엔지니어

- 메카트로닉스 엔지니어

- 운영 관리자

- Process Improvement Specialist

- 제품 디자이너

- Quality Assurance Engineer

- 로봇 공학 엔지니어

- 공급망 관리자

- Validation Engineer

뉴스 피드

주요 채용 정보

온라인 과정 및 도구